We recommend an NVIDIA Quadro® or AMD FirePro™ / Radeon Pro card with 4GB or more of memory. When purchasing a new computer for Mastercam, one of the most important component is the video card. For large toolpath generation and simulation, we recommend 32GB of RAM. We recommend a minimum of 8 GB of memory. When Mastercam uses all available RAM, it switches to using virtual memory space, which is stored on the hard drive and will dramatically slow the system down. We typically see a 50% reduction in toolpath calculation time with the latest Intel i7 or Xeon processors. Toolpath calculation and Simulation will generally run faster with a multi-core processor. With each release, more and more aspects of Mastercam are becoming multi-core processor aware. The processor speed will impact how fast the software will calculate and complete tasks. Ramp contour toolpath is more favorable than any other toolpaths.Mastercam X7 MU2 was the last release to support Windows 7 32-bit OS. Experimentation reveals that zigzag toolpath is more favorable than any other strategies for the machining of turbine blade for minimum cycle time. Actual machining is done to validate the software simulation time. The objective of simulation is to generate the shortest tool-path for contouring operation. Different contour toolpaths being simulated are 2D, chamfer 2D, Ramp, Remachining and Oscillating. Different toolpath generation methods are studied to select the best one to find out optimized cycle time. Both productive time and non-productive times (airtime, tool change time) are considered for optimization.

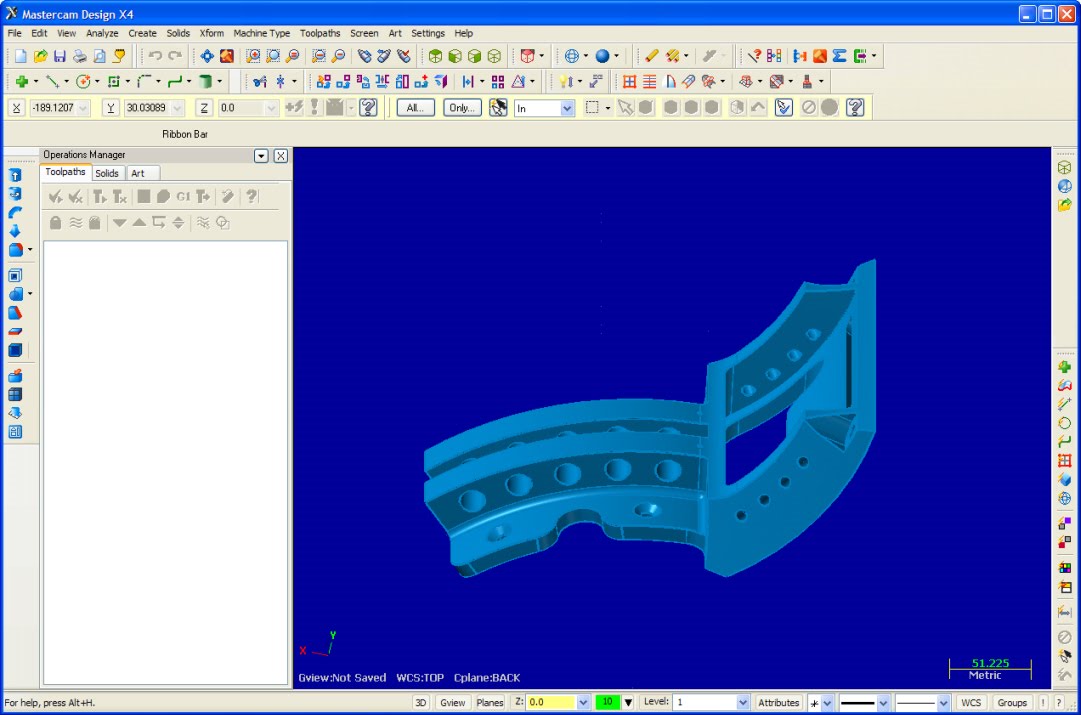

Most of the research work is focused on cutter path generation with the main aim on reducing total cycle time. Cutting Parameters used for machining are spindle speed, feed, tool diameter, plunge-rate, and depth of cut. Different contouring toolpaths are simulated in MasterCAM® prior to machining of turbine blades. Toolpath optimization of turbine blade using MasterCAM® software results in reduction of machining time. This paper presents optimization of toolpath for turbine blades in vertical machining centre (VMC). Contouring operations are generally used for this purpose. Turbine blades are complex shapes and difficult to machine on CNC. Today many industries use CNC machines for production of turbo machinery components like turbine blades, impellers, rotors, propellers etc.

0 kommentar(er)

0 kommentar(er)